Mine ventilation, refrigeration, and cooling engineering consultants BBE Group have released the 2021 version of their flagship VUMA-network software to the industry — at no cost. It’s a bold move that puts an advanced, industry-leading interactive mine ventilation network simulation tool into the hands of mine and ventilation engineers across the world.

“Intense temperatures, humidity, diesel fumes and gasses are health hazards for underground miners. This makes good ventilation non-negotiable,” says Miguel Coelho, Ventilation Engineer at BBE. “However, with so many complex factors impacting environmental conditions, dangerous shifts can be hard to predict. BBE’s VUMA-network software, with its ability to simulate multiple variables, addresses this issue. It also drives system optimisation and energy efficiency, a critical cost and operational factor for mines in South Africa. Making it available to industry at no cost puts everyone ahead.”

Built on a Microsoft platform, VUMA-network’s most recent upgrade advances it to 64-bit computing with a supercharged graphics engine. The solution has also been enabled for global use, with support for different languages, namely Chinese, Polish and Spanish, and the integration of country-specific features and design criteria. In addition, the software is vendor-agnostic – it will integrate will all major industry software and solutions – and users are not required to have to have a relationship with BBE to use it.

VUMA’s simulation technology – proven

VUMA-network is proven software. It has been developed and used by BBE engineers for over 20 years to plan, design, operate and troubleshoot ventilation and cooling systems in underground mines around the world. It is already in use at most mines in South Africa.

“With advanced simulation technology, mining and ventilation engineers can gain complete control over the crucial ventilation and cooling aspects of mining processes across a range of mining methods,” notes Coelho. “This is especially important as energy costs rise and safety regulations ramp up. With mine planning software becoming increasingly sophisticated, the kind of graphic ventilation network detail and troubleshooting that software like VUMA-network can provide is becoming invaluable.”

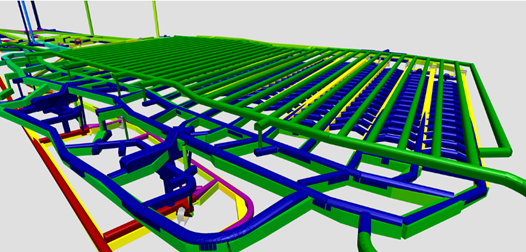

VUMA-network simulates airflow, heat loads, gases (including radon, a radioactive gas released in uranium mining), dust, diesel particulate matter from diesel machinery, and impacts of blast clearances and underground fires. Simulations are based on the specific conditions in a mine – the type and intensity of work, the performance of cooling infrastructure, use of machinery, and mining method employed.

These inputs may be collected from mine systems and sensors, imported directly from various mine-plan formats, or defined by mining engineers. This facilitates planning and design of systems, energy optimisation, fault finding, and troubleshooting, what-if scenario analyses, dust and/or gas tracing, refrigeration cooling system design, and verification of environmental performance. Importantly, it allows engineers to identify hinge points where infrastructure can be improved and to test hypotheses before acting.

The differentiating factor

“What differentiates the VUMA software is the quality of inputs that have, and continue to inform its algorithms,” says Coelho, “and the fact that it has been built for engineers by engineers.”

Initially developed by the CSIR in the early 1990s for use in South African mines, the software was acquired by BBE in [2009]. With continual updates based on user feedback and evolving needs, it is one of the industry’s best informed and most accurate solutions.

For example, VUMA’s heat flow algorithms have been developed through extensive empirical data gathered from some of the deepest and hottest mines in the world. Mine heat load prediction is an extremely complex science involving geothermal rock heat flow and the effect of hot rock conduction, mining cycle activities, water use activities and changing conditions on all the various rock surfaces. It also depends on refrigeration and air-cooling tactics, and the use of equipment and machinery, and their work cycles. This attention to detail allows the integrated solution’s engine to accurately calculate the heat flow from numerous sources.

Digital twin, proactive exhaust ventilation

“Mines everywhere are increasingly making use of advanced technologies to improve efficiency, optimise operations, safety and productivity. BBE’s VUMA-network is an important addition to their technology stack,” says Coelho. “It’s a proven solution, and it comes with a range of specialised add-ons that can help mines take the next step toward transformation and automation.”

“The VUMA suite is built on the insight BBE has obtained through its projects at major mines in South Africa and across the globe. We hope that use of VUMA-network continues to add value to the industry, helping to make mines safer and more profitable,” concludes Coelho.